| Product design, research & development |

We are involved in the early phase of client's new product development, in which, we make 3-demension design for all sections, from product appearance to all details by using 3D design software, and then stringently research and examine the design. Flow analysis of plastics, assembly check and intervention examination all are carried out with the assistance of CAE software so as to ensure high-resolution and high quality early in the beginning stage. We are involved in the early phase of client's new product development, in which, we make 3-demension design for all sections, from product appearance to all details by using 3D design software, and then stringently research and examine the design. Flow analysis of plastics, assembly check and intervention examination all are carried out with the assistance of CAE software so as to ensure high-resolution and high quality early in the beginning stage. |

| |

NC processing data Integration NC processing data Integration

Advanced CAM software ,Outputting precise design data provide efficient program for the processing on machine tool of' all different parts. Advanced CAM software ,Outputting precise design data provide efficient program for the processing on machine tool of' all different parts.

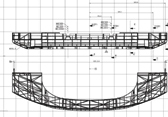

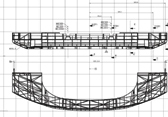

Mould Design

3D mould design are done with efficient design software (Pro/E). Design data for mould base, lever, cooling system, and standard parts are entered into server to be part of a database which can be quickly drawn to finish the assembly of the whole set of mould. In this way, we can make efficient, precise, and standardized mould design. 3D mould design are done with efficient design software (Pro/E). Design data for mould base, lever, cooling system, and standard parts are entered into server to be part of a database which can be quickly drawn to finish the assembly of the whole set of mould. In this way, we can make efficient, precise, and standardized mould design. |

| |

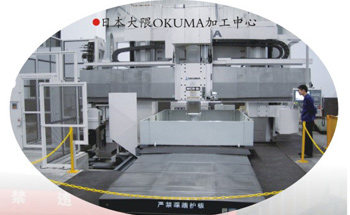

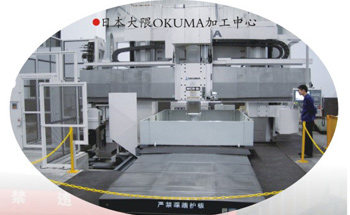

Mould Making Mould Making

We have a whole set of automatic, high-precision computer numerical control processing machines. Efficient processing technology help to maintain consistent quality and precision of mould parts production. (See detailed remarks for equipment list). The connection of various processing machinery through computer network enable the direct transmission of CAD/CAM data. We have a whole set of automatic, high-precision computer numerical control processing machines. Efficient processing technology help to maintain consistent quality and precision of mould parts production. (See detailed remarks for equipment list). The connection of various processing machinery through computer network enable the direct transmission of CAD/CAM data. |

| |

Quality assurance Quality assurance

High-precision 3D coordinate measuring machine enable us to conduct thorough check and test on trial product against draft so as to ensure every measurement of finished product delivered to our client meet requirement. High-precision 3D coordinate measuring machine enable us to conduct thorough check and test on trial product against draft so as to ensure every measurement of finished product delivered to our client meet requirement. |

|

|

Mould Making

Mould Making Quality assurance

Quality assurance